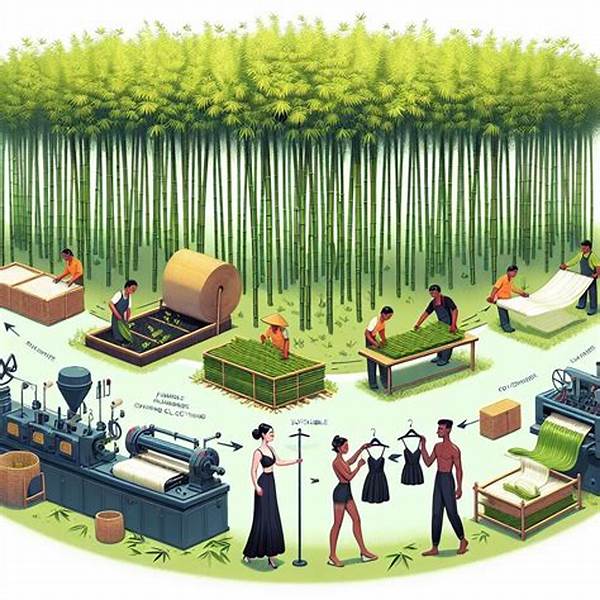

In a world increasingly attuned to sustainable choices and environmentally conscious living, bamboo-based apparel manufacturing techniques stand out as a beacon of innovation and responsibility. With the global community shifting towards eco-friendly fashion, the time has come to embrace bamboo as a vital resource in apparel production. This remarkable plant offers unparalleled benefits—superior comfort, durability, and a smaller ecological footprint—making it an ideal alternative to traditional textiles. Join us on this journey as we explore how bamboo-based methods are revolutionizing the apparel industry and why you should be part of this sustainable movement.

Read Now : Vintage Thrift Shop Bargain Deals

Understanding Bamboo-Based Apparel Manufacturing Techniques

Bamboo-based apparel manufacturing techniques are steadily gaining traction, and for good reason. The process is not only environmentally friendly, but it also offers numerous benefits to consumers and producers alike. By utilizing the natural antibacterial properties of bamboo, these techniques ensure that the end products are not only soft and breathable but also resistant to odors and harmful bacteria. Moreover, bamboo grows rapidly, often without the need for pesticides or excessive water, making bamboo-based production inherently sustainable.

The process begins with the careful selection of high-quality bamboo, which is then processed into pulp, and subsequently spun into fibers. These fibers are then woven or knitted to create fabric. What sets bamboo-based apparel manufacturing techniques apart is their minimal environmental impact. Traditional textile production often involves harmful chemicals and a high carbon footprint. In contrast, bamboo-based processes require fewer chemicals and less water, aligning perfectly with the ethos of sustainability.

Switching to bamboo-based apparel manufacturing techniques is not merely a trend but a necessary shift towards a better future. Brands that adopt these practices not only contribute to preserving the environment but also cater to an ever-growing market of eco-conscious consumers. Emphasizing comfort, durability, and minimal environmental disruption, bamboo-based apparel is truly the fabric of the future.

Advantages of Bamboo-Based Apparel Manufacturing Techniques

1. Bamboo-based apparel manufacturing techniques ensure sustainability, as bamboo grows rapidly and requires minimal resources.

2. These techniques reduce the environmental impact by using fewer chemicals and less water compared to conventional textile processes.

3. Bamboo textiles are naturally antibacterial, making bamboo-based apparel manufacturing techniques a hygienic choice for clothing.

4. Comfort and durability are key benefits of bamboo-based apparel manufacturing techniques, offering soft, long-lasting garments.

5. Choosing bamboo-based apparel manufacturing techniques means supporting eco-friendly fashion and contributing to a healthier planet.

The Innovation of Bamboo-Based Techniques

The innovation behind bamboo-based apparel manufacturing techniques lies in their ability to ingeniously combine nature and technology. By leveraging bamboo’s natural properties, these techniques produce garments that are not only eco-friendly but also enhance the wearer’s experience. Soft to the touch and exceptionally breathable, bamboo-based apparel offers comfort that is hard to match with traditional textiles. Consumers who choose these garments not only invest in quality but also in a sustainable lifestyle.

Furthermore, bamboo-based apparel manufacturing techniques align with a broader movement towards responsible living. As more people become aware of their environmental impact, the demand for sustainable fashion continues to rise. By adopting these innovative techniques, brands can fulfill consumer desires for high-quality, eco-conscious products. In doing so, they not only satisfy market demands but also position themselves as leaders in the burgeoning field of sustainable fashion.

Read Now : Modern Modest Casual Fashion Women

The Market Impact of Bamboo-Based Apparel

The rise of bamboo-based apparel manufacturing techniques is not just an environmental victory; it’s also a smart business move. The eco-conscious consumer base is rapidly expanding, and brands that embrace bamboo-based methods gain a competitive edge. By showcasing their commitment to sustainability, these companies attract a loyal customer base that values ethical practices. Moreover, the versatility and wide-ranging applications of bamboo textiles allow for a diverse product line, from casual wear to high-performance athletic gear.

Innovation in bamboo-based apparel manufacturing techniques opens up new avenues for creativity and design. With the ability to produce unique textures and patterns, brands can meet the diverse aesthetic preferences of their audience. This flexibility, combined with the inherent benefits of bamboo, positions these techniques at the forefront of a fashion revolution. Adopting bamboo-based methods is a strategic move that aligns profitability with responsibility, offering a win-win proposition for businesses and the planet.

Embracing Bamboo-Based Apparel for a Sustainable Future

Adopting bamboo-based apparel manufacturing techniques is crucial for ensuring a sustainable future. As the fashion industry grapples with its environmental impact, bamboo offers a viable solution. The plant’s rapid growth and low resource requirements make it an ideal choice for sustainable textile production. By opting for bamboo-based methods, companies significantly reduce their carbon footprint and promote responsible practices.

Moreover, bamboo-based apparel manufacturing techniques foster innovation and elevate consumer experiences. The resulting garments are not only eco-friendly but luxurious and comfortable. The natural qualities of bamboo fibers provide superior moisture-wicking and temperature regulation, making them ideal for various climates and lifestyles. By embracing these techniques, brands contribute to a circular economy that prioritizes long-term sustainability over short-term gains.

The Future of Bamboo-Based Apparel Manufacturing

The promise of bamboo-based apparel manufacturing techniques extends beyond ecological benefits. As more brands recognize their potential, the industry is set for a transformation. These techniques offer a blueprint for integrating sustainability into mainstream fashion, appealing to a demographic that is increasingly aware of its environmental footprint. The shift towards bamboo-based production is not just a trend but a movement towards a balanced relationship with nature.

By investing in bamboo-based apparel manufacturing techniques, manufacturers and designers position themselves as pioneers of sustainable innovation. This forward-thinking approach ensures they remain relevant and competitive in a rapidly changing market. Ultimately, the future of fashion lies in practices that harmonize with the environment, and bamboo-based apparel manufacturing is leading the way toward a more sustainable industry.

Summary of Bamboo-Based Apparel Manufacturing Techniques

In conclusion, bamboo-based apparel manufacturing techniques represent a significant leap forward in eco-friendly fashion. By utilizing bamboo—a fast-growing, resource-efficient plant—these techniques offer a sustainable alternative to traditional textile processes. The resulting garments provide unmatched comfort, breathability, and durability, appealing to consumers who prioritize quality and environmental responsibility.

As the demand for sustainable fashion continues to rise, bamboo-based apparel manufacturing techniques position businesses at the forefront of this movement. These methods align profitability with ethical practices, creating an opportunity for brands to lead the charge towards a more sustainable future. By embracing bamboo-based production, companies not only reduce their environmental impact but also foster a loyal consumer base that values their commitment to the planet.